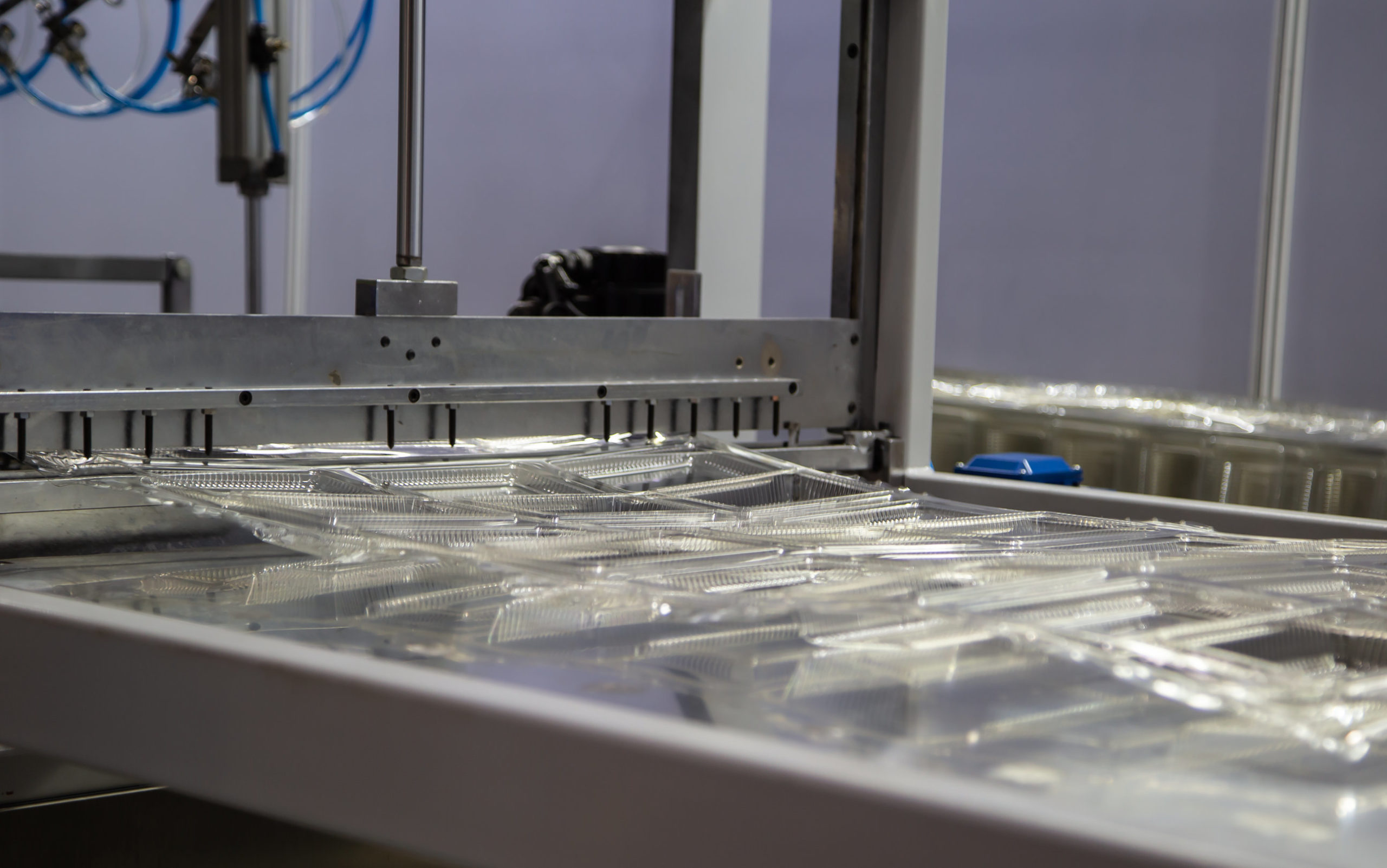

High-speed tray forming machines are essential for any retail business poised to begin national or regional distribution. Your display trays are part of your brand identity and, in some cases, the first thing your potential customer sees when discovering your product. Present your product in professionally formed and folded trays that are customized to your exact product specifications with Econocorp’s line of high-speed tray formers, including the Econoform, Econolock, Reverse Triseal, and T-System. Our heavy-duty tray formers can:

-

Slash your production and labor costs.

By forming trays at speeds of 25+ per minute and never requiring breaks due to fatigue, high-speed tray formers outperform employees and provide more consistent results. They eliminate the need for human tray formers, cutting labor costs and improving profit margins.

-

Form trays customized to your exact specifications.

Tray formers are typically built to your exact product specifications, allowing you the choice of many tray materials and sealing methods, such as hot glue, corner lock, or hot air. Forming customized trays reduces waste, which in turn cuts costs, all while delivering your product in a professional-looking, custom-fit carton. Products that look custom produced are quicker to catch the retail consumer’s eye and can be sold for higher prices.

-

Keep you stocked in ready-to-pack cartons.

You’ll never be waiting on display or transport trays again with a high-speed tray former running from open to close, or even 24/7. These machines can hold large amounts of tray blanks, allowing operators to set them once at the beginning of the shift and run for hours without more interaction. Assuming a conservative 25 trays per minute, you can feasibly produce 12,000 perfectly and consistently formed trays in just one 8-hour shift. Finished trays are neatly stacked and ready to be packed with display-ready products.

-

Free up employee time for other tasks.

Employee time in your company is most likely better used on more advanced tasks than tray forming. Using employee labor to form trays wastes their potential and leads to employee boredom, which also affects productivity, and ultimately, your bottom line.

-

Easily integrate into your existing production line.

High-speed tray formers boast a small footprint, taking up minimal square footage in your production line. Easily pair the tray former with other end-of-production technologies, such as erectors, labelers, or packers, to create a customized and efficient production line for your products.

-

Keep your brand consistent across all locations.

Consistently formed and folded trays will create a smooth and unifying brand for your business across all locations where your products are sold. You want retail consumers to be able to immediately identify all packaging related to your products, and creating uniform trays is one way to help bring brand awareness.

High-speed tray forming machines solve a big problem for medium to large size production businesses that need consistent, quality packaging at a faster rate than employees can provide. Econocorp is a US-based source of high-speed tray formers that has many solutions to take your business from local to beyond. Call us at (781) 986-7500 to discuss your production machinery needs today.