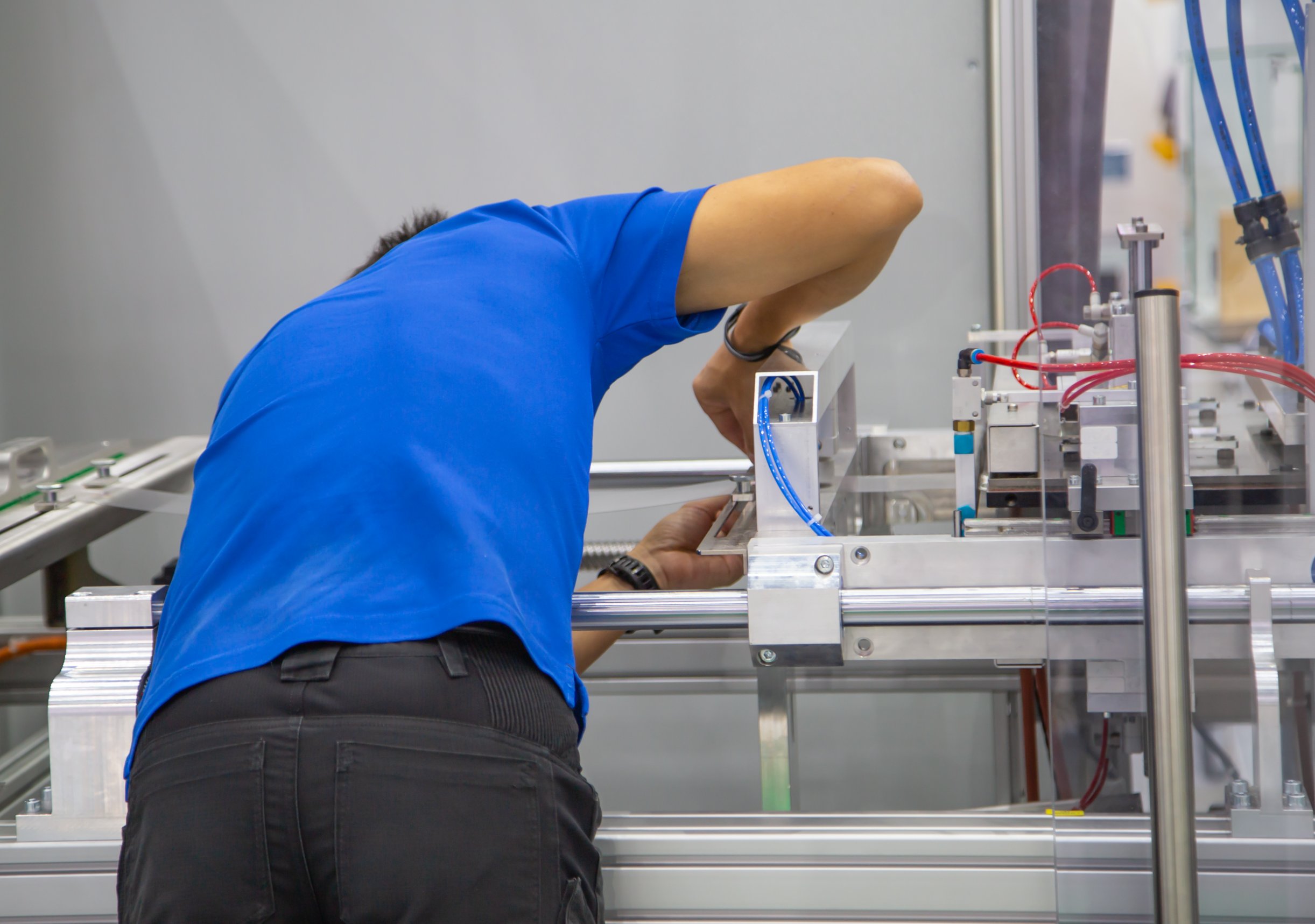

Companies purchase and install new equipment when they are enhancing operations, increasing capacity, or when existing equipment reaches the end of its usable lifespan. New packaging equipment is always an exciting install to make since it often ushers in less work for employees, reduced packaging waste, and more consistent product packaging. Installing new packaging equipment properly is essential for it to perform optimally and last through its lifespan. In this post, we’ll go over the basics of packaging equipment installation with our handy checklist:

⃞ Review Equipment Specifications

Before new packaging equipment is purchased, the manufacturer specifications should be completely reviewed to ensure they are compatible with your current floorplan and utility setup. Always refer back to these specifications when making installation decisions, as this is the master guide to what the packaging machine will need to operate at full capacity. If modifications are needed to make the new equipment fit or work correctly, make them before the machine arrives if possible.

⃞ Assess Proposed Installation Site

Evaluate the proposed installation site to ensure that it is ready for the new equipment. This involves checking for adequate space, ensuring that the floor can support the weight of the equipment, and confirming that there are no overhead obstructions. Also make sure that the installation site is accessible for delivery vehicles and equipment needed during the installation process.

⃞ Setup Necessary Utilities

Some equipment will require specialized electrical, plumbing, ventilation, or other utility setup to be done at the installation site. Coordinate with utility providers to make any necessary changes or modifications before the equipment arrives.

⃞ Permits and Inspections

Double check with your state and local governments for special regulations on the installation of equipment, as some areas do have rules and conditions for certain equipment installations. If permits are required, apply for them prior to the arrival of the machine to avoid having your new packaging equipment just sitting around waiting for paperwork to come through. Also, be prepared for any inspections that may be required as a condition of receiving permits.

⃞ Coordinate with Vendors and Installation Teams

Effective communication with equipment vendors and installation teams is essential. Confirm delivery dates, installation start times, and any prerequisites needed from your side. Ensure that the installation team has clear access to the site and any additional equipment they might need. Assign one person as the point of contact for the equipment installation and communicate with that person regularly for status updates, problem resolution, etc.

⃞ Prepare Your Team

Prepare all employees for the new equipment installation by communicating early and regularly with them about the proposed timeline, required changes during installation, workflow interruptions, etc. Consider training sessions or group meetings to discuss these changes, since having everyone on board will minimize disruptions to business operations.

⃞ Safety First

Collaborate with your company safety officer to make a safety plan for the new equipment installation. This includes reviewing safety information for the equipment, preparing any necessary safety equipment, marking off the installation area, and ensuring all involved understand how to operate safely around the new installation. Safety briefings or checks throughout the installation process will also be helpful.

⃞ Make a Backup Plan

If something can go wrong, it will go wrong…this is especially true during equipment installations. Develop a backup plan to address potential delays or problems, such as delivery delays or unexpected site issues. Having this plan can help keep the project on track, on budget, and minimize stress for you and everyone else.

⃞ Post-Installation Checks

After the equipment has been installed, test it thoroughly to ensure it is operating correctly before allowing any employee to train or operate it. Check all features, connections, and settings, and review the installation results against the manufacturer’s expected guidelines. Any issues should be addressed immediately to prevent breakdowns and diminished performance.

Let Econocorp Help With Your New Packaging Equipment Installation

By following this checklist, you can ensure a smooth and efficient installation process for new packaging equipment. Proper preparation not only facilitates a hassle-free installation but also contributes to the equipment’s long-term success and reliability. When you purchase your new packaging equipment with Econocorp, you have all of our knowledge at your disposal. We’ll review all the ins and outs of installation with you, conduct on-site visits, and provide troubleshooting assistance throughout the installation process. To find out more about how Econocorp makes new packaging equipment installation a breeze, call us at 781-986-7500 or email info@econocorp.com today!