Automation is more than just a trend in the packaging industry…it’s a powerful tool that’s here to stay. According to data from Precedence Research, “the global packaging automation market size was estimated at USD 69.18 billion in 2022 and it is expected to hit around USD 145.93 billion by 2032”. That’s a huge expansion in ten short years, but the reasoning for this growth is clear – automation boosts efficiency, consistency, and productivity…and ultimately, profitability. At Econocorp, our extensive experience with packaging line automation gives us a unique insight into how to implement this game-changing technology without sacrificing quality. Here are five ways that automation on your packaging line can improve the efficiency of daily operations:

Enhanced Speed & Consistency

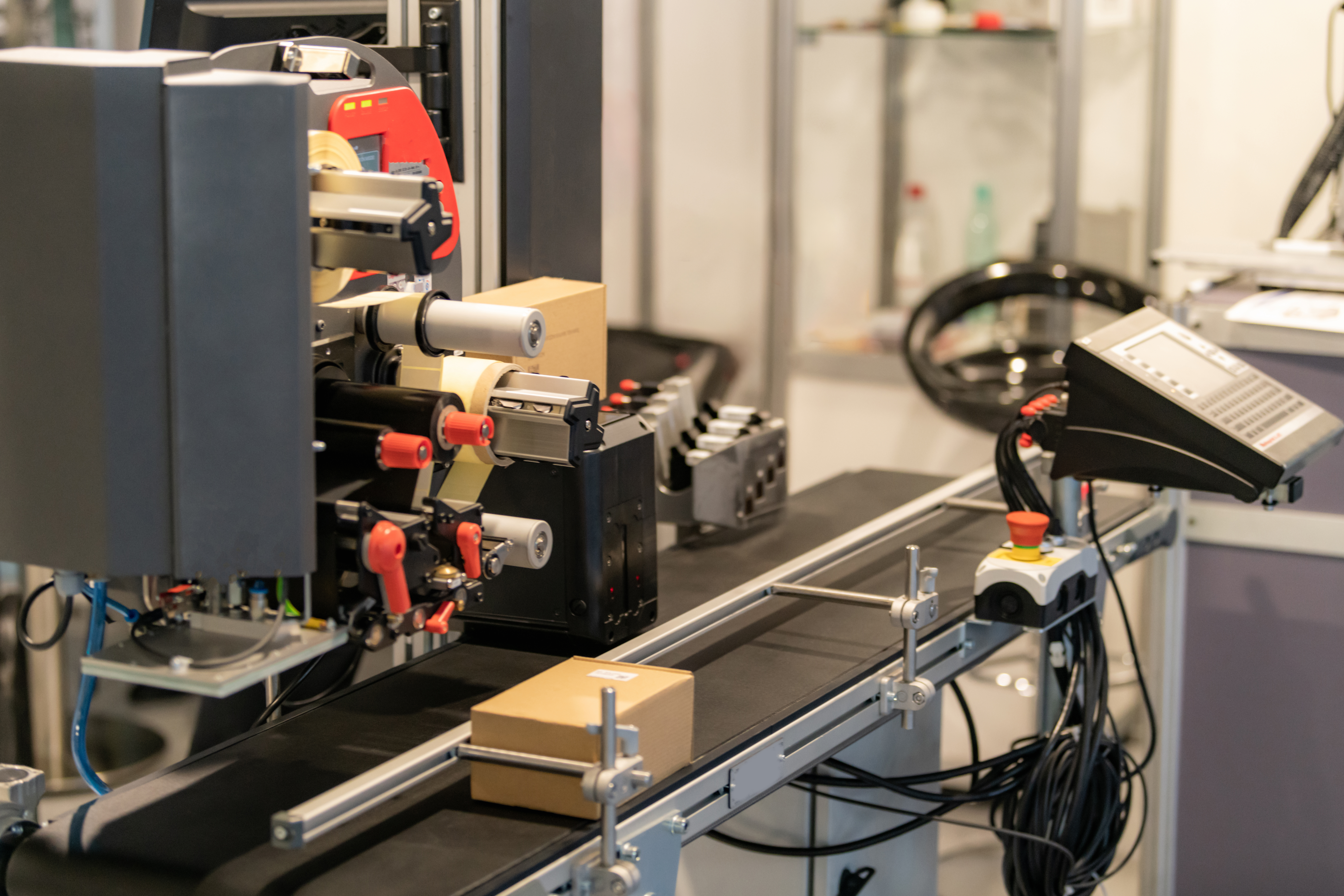

The main benefit of automation is a boost in packaging speed along with increased consistency of branding. With automation, your packaging line can finally meet high quotas without any sacrifice in quality, delivering a consistent and coherent brand image from the packaging line to the retail shelves.

Reduced Labor Costs & Human Error

Human errors on the packaging line can take a toll on production quotas and overall profitability. When an error causes the entire line to go down, that’s potential revenue going to waste, often over a repetitive and easily automated task. By implementing automation for these monotonous and simple tasks, human resources can be reallocated to more complex tasks, cutting labor costs, minimizing waste, and preventing rework.

Improved Worker Safety

Automation in a packaging line means that there is a lower chance of a workplace accident, especially those associated with repetitive motions or heavy lifting. There’s no reason to put human workers at risk over a task that is easily completed with automation. Furthermore, at Econocorp, we build all of our machines with worker safety as a top priority, including built-in operator safety controls and cutoffs, ergonomic designs, and reduced human-machine interaction.

Flexibility to Accommodate Various Products

No matter what size or shape packaging your products require, Econocorp has an automated packaging solution that can accommodate. Our line of cartoners, tray formers, and case packers can handle everything from tiny cosmetics packaging to large bulk-sized items, switching automatically between different package sizes and configurations seamlessly with minimal downtime for setup.

Scalability for Business Growth

Once your product takes off and sales are sky high, you’ll need a packaging line that can keep up with the increased demand. With automation solutions on Econocorp’s line of packaging equipment, your packaging operation can scale up easily as your business grows. This means your operators won’t need to learn new machinery just to increase productivity, and the same level of quality and efficiency will still be there.

Ready to Boost Efficiency With Packaging Line Automation?

Automation in packaging is not just a trend; it’s an innovative solution that offers real benefits on the packaging line – from enhancing speed and consistency to improving safety and scalability, the advantages are apparent and clear. If you’re ready to take your packaging line to the next level of efficiency without compromise, Econocorp’s line of equipment with automation features is here to support you on your way to success. For more information on our range of packaging equipment and machinery, call 781-986-7500, email info@econocorp.com, or message us online.