Integrated Tray Forming, Loading, and Sealing for Efficient Packaging

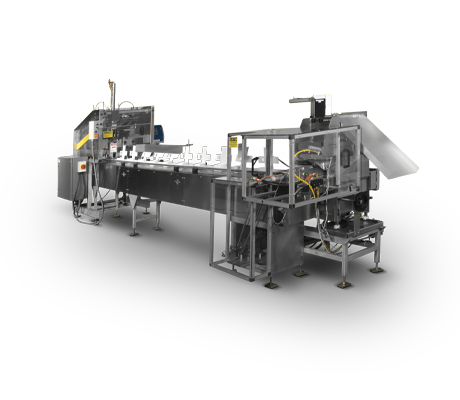

The Econocorp T-System is a compact, fully integrated system designed to automate the forming, loading, and sealing or closing of hooded cover trays. Combining a tray former (EconoLock or EconoForm), an intermittent motion flighted conveyor, and a tray sealer (Reverse Triseal or Straight-line Gluer), the T-System delivers a seamless packaging solution for a wide range of applications.

Capable of speeds up to 25 trays per minute, the T-System supports a variety of tray styles, including glue-sealed trays, corner lock trays, and simplex locking trays, formed from either paperboard or corrugated materials. With adjustable intermittent and intermittent motion throughput settings, the T-System provides the flexibility to accommodate a wide range of packaging formats, production volumes, and operational layouts.

Seamless End-to-End Tray Packaging Automation

The T-System delivers complete automation by integrating tray forming, loading, and sealing into one cohesive, streamlined process. By combining a tray former, intermittent motion flighted conveyor, and tray sealing station into a single, straight-line configuration, it ensures consistent tray quality while optimizing floor space utilization.

Its modular design allows for flexible adjustments based on tray style, size, or material, making it easy to adapt to specific product or production requirements. Whether operating at intermittent speeds for delicate products or intermittent motion for higher-volume applications, the T-System provides dependable, high-quality performance—making it an ideal solution for both new and existing packaging lines.

Built for Flexibility, Efficiency, and Hygienic Operation

The T-System is designed to meet the evolving needs of today’s packaging operations, offering a combination of flexibility, efficiency, and hygienic construction. Built with a sanitary design and available washdown options for environments requiring enhanced cleaning protocols, the T-System is well-suited for industries such as food, bakery, frozen goods, and other applications where cleanliness is critical.

With adjustable intermittent and intermittent motion throughput settings, the system can easily adapt to varying production demands, whether running short batches, seasonal products, or higher-volume, intermittent operations. Its ability to adjust speeds and throughput ensures optimized performance while helping maximize uptime, reduce downtime during changeovers, and maintain high packaging quality.

Supporting both paperboard and corrugated trays across a flexible size range, the T-System delivers the versatility needed to handle a wide variety of product types and tray configurations. All of this is achieved within a compact, space-saving footprint, making it easy to integrate into both new production lines and existing layouts without requiring major facility modifications.

T-System Specifications

| Specifications | Details |

|---|---|

| Speed | Up to 25 trays per minute |

| Tray Styles | Glue-Sealed, Corner Lock, Simplex Style |

| Materials Supported | Paperboard & Corrugated |

| Size Ranges | Min: 4" x 3" x 1" Max: 9" x 7" x 3" (custom sizes available) |

| Power Requirements | 220V, 50/60 Hz, Single Phase |

| Air Requirement | 80 PSI (5.5 bar) |

| Footprint | 235.56” L x 60.06” W x 88.85” H |

| Shipping Weight | Less than 1200 lbs (545 kg) |