Inspiring the Next Generation of Engineers and Packaging Automation Leaders

Keeping Manufacturing and Automation at the Forefront

We’re on a mission to help build the next generation of engineers and thinkers to help keep automation and manufacturing at the forefront.

Because it’s not just crucial to our success, it’s vital to our customers’ success as well.

Many students don’t know about the world of automation, and we’re here to change that because who wouldn’t want to work for a company that helps your favorite brands automate their production facilities?

Debunking the Myths of Modern Manufacturing

But too often manufacturing gets a bad rep, as you often hear these common words:

It’s dark, dirty, and dangerous

But what if that wasn’t true? In fact, 99% of these manufacturing plants lay in a world full of automation, exciting emerging technology, in clean, well-lit and safe production plants (including ours!). These places use robotics, precision motion, and advanced control systems to create and package their products to ensure they show up to your favorite store for you to purchase.

What’s even more interesting is there are a large number of companies dubbed machine builders who help your favorite brands automate their production facilities—creating consistent production flows, safer work environments, and a multitude of new skilled jobs.

Inside Econocorp: Where Learning Meets Hands-On Manufacturing Experience

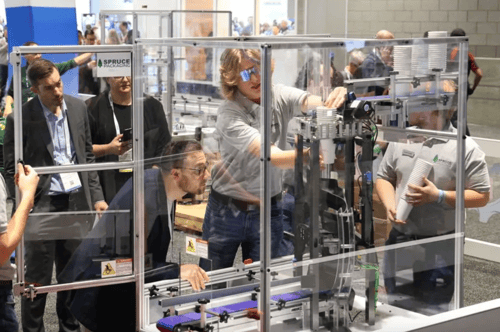

Welcome to a small piece of the puzzle at Econocorp, where we design, build, and test all different types of cartons, carton formers, loaders, and sealers.

When it comes to any discipline, especially engineering, we always find students who started or had a lot of exposure in hands-on environments early shine over those who don’t. And why? Because they learned how things are built, machined, welded, etc.

But more importantly, they learn that mistakes happen, and your design work directly impacts the production employees responsible for making it come to life. They learn how to work through challenges and get a new appreciation for engineering work. It also gives them a deeper understanding of how things work, so parts and assemblies are designed simpler and more likely to work in real life.

Because—yes again—they went through that struggle and don’t want others to also.

Real Stories: Sam’s Start on the Shop Floor

Just take Sam, our COO’s, word for it. He started working in the assembly department when he was a junior in high school. He will mostly credit the summers spent on our production floor for his deep understanding and knowledge of what we do.

Growing the Automation Workforce Through Community Partnerships

Here’s what we’re doing to make a difference, not only to help us, but to help spread the world of automation around the Boston area and help as many students as we can.

Sam is both a board member of the PMMI Foundation as well as the chairperson for PMMI’s Future Workforce Committee. He’s deeply committed to ensuring the future of our industry is filled with bright and talented individuals, not just for Econocorp but for everyone.

Through his work with PMMI, he’s leading the charge to encourage other PMMI member companies to get involved with the next generation through matching funds, manufacturing summer camps, and student attendance at trade shows.

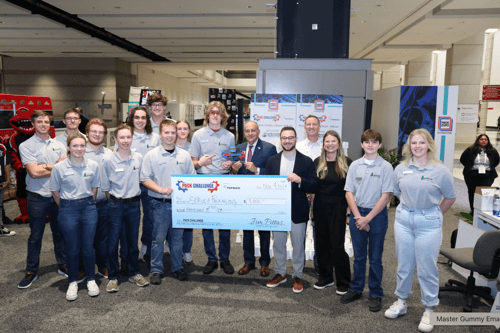

Along with that, he’s playing a critical role in expanding Pack Challenge, PMMI’s real-world, end-to-end design and build competition in which high school teams design, build, debug, and test a piece of packaging machinery to compete at Pack Expo.

Partnering with Local Schools and Programs

Randolph High School: Project Lead the Way Internships

Randolph High School, being in Randolph, is a full support of our local community. Randolph has a Project Lead the Way curriculum in which students must complete an internship at the end of their senior year in a field of interest to graduate.

Following a similar structure to our RISE interns at Xaverian, two students—Matthew and Michelle—joined our team for April and May, and enjoyed it so much they asked to spend the remainder of the summer collaborating with the Xaverian students.

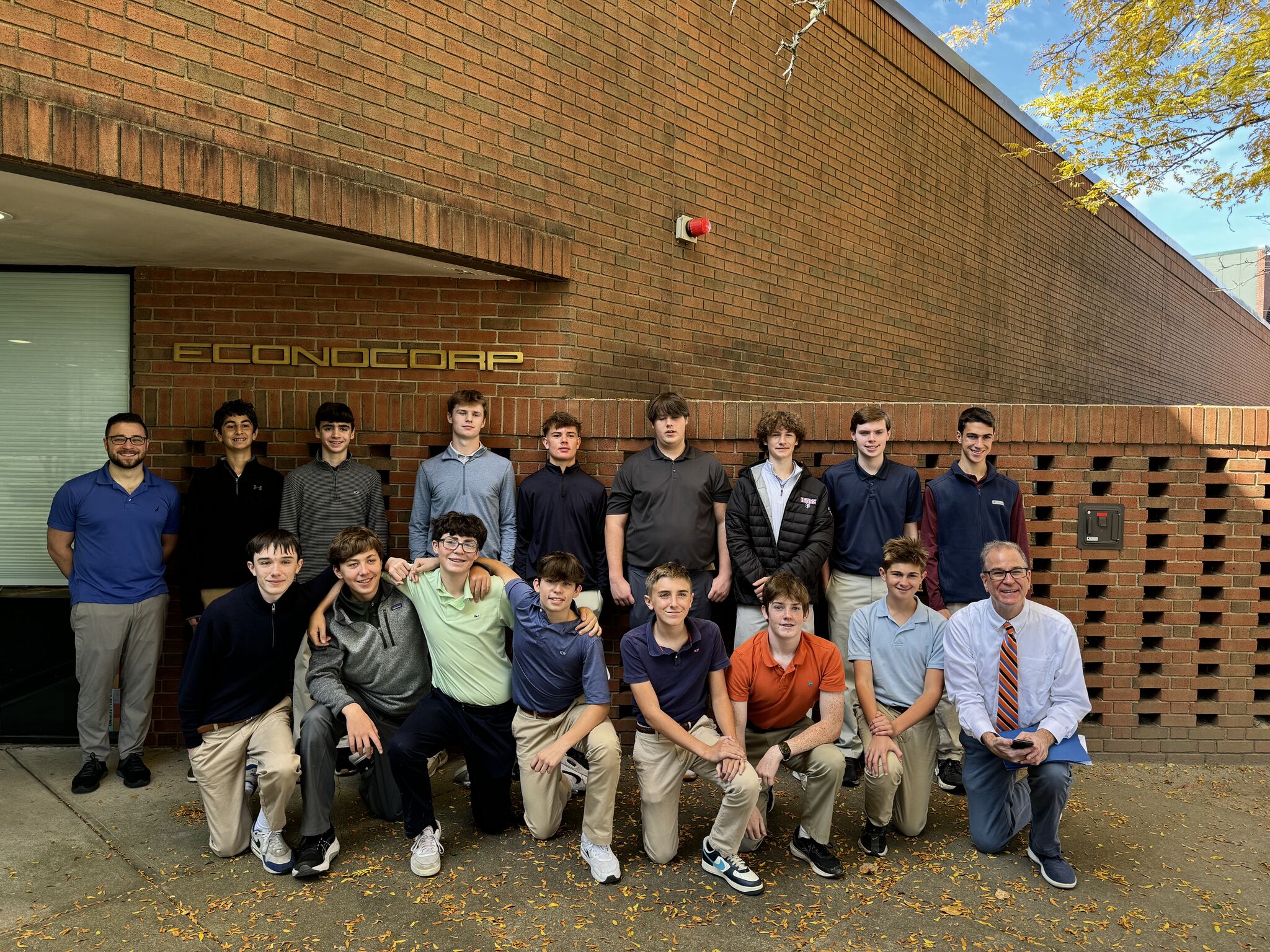

Xaverian Brothers High School: RISE Internships and FIRST Robotics

Xaverian Brother High School has been educating young men for a very long time. Recently, they created an X-ploration Center filled with 3D printers, lasers, and all types of other power tools.

Along with this came their FIRST Robotics team for FTC. With matching funds from the PMMI Foundation, we are able to support the Xaverian team’s season as well as help send them to the World Championships in 2024.

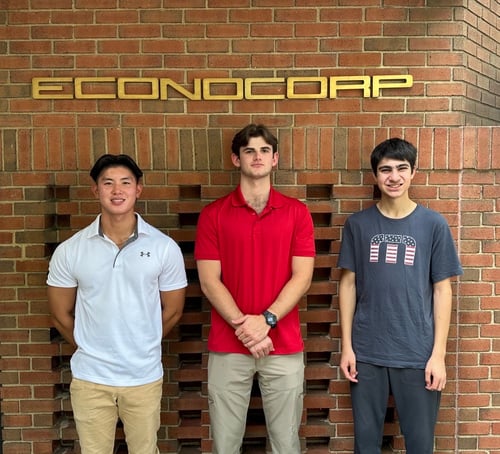

Xaverian also created a new internship program called RISE. Through this, we have had students apply to join our assembly floor for the summer—ideally students wanting to go to a four-year engineering college after graduating high school.

This year, two students—Charlie and Sam—joined the team along with last year’s intern Haig. They will spend the summer building EconoCore machines, getting exposure to all facets of our production floor.

Melrose High School: FIRST Robotics Support

Melrose High School is another opportunity to support a FIRST team in FRC. Meghan, one of our design engineers, is a mentor to the team and was a member during her time in high school.

She decided to become a mentor from the experience of helping the Xaverian FIRST team. With PMMI Foundation matching funds support, we are able to help them with their FRC season and competitions.

Northeastern University: Co-op Program in Action

Northeastern University is at the forefront of cooperative education. Both Sam and Carter, our Director of Manufacturing, graduated from here and benefitted greatly from the co-op program.

We recently wrapped up our first mechanical engineering co-op Kristen, who was with us from January to June. We now have a new co-op Riley joining us from July to December.

This 6-month co-op is meant to give students a hands-on, real-life job experience while still being in university on a break from classes. Kristen and Riley get to work on a multitude of things—from engineering improvements to real customer projects to joining weekly engineering level 10 meetings.

Rutgers

Sam has been invited in recent years to give a guest lecture to the packaging machinery class to help the future carton/case/tray designers learn how and why it’s important to collaborate with OEMs; as the materials that run through our machines directly impacts the performance, uptime, and overall equipment effectiveness (OEE).

They also go into depth of the struggles and how to effectively collaborate between a packaging engineer wants and marketing wants for the user experience. While maybe not the type of people we regularly hire, we find it’s important to ensure our end users will be able find the right talent. A lot more goes into the little box of your favorite brands than you might think.

Purdue Northwest University: Real-World Innovation in Indiana

Purdue Northwest University, maybe not exactly in the Boston area, is a manufacturing hot spot in the northwest part of Indiana. They have a very strong mechatronics department and were the first school Econocorp used PMMI matching funds to support.

We have worked hand in hand with PNW on numerous senior design projects that have resulted in the development of new products like fully adjustable beverage gates.

PNW also has a very sophisticated Commercial Excellence Center and PLC labs, which we have also supported with monetary donations.

Worcester Polytechnic Institute

Similar to PNW, we have participated with WPI to sponsor senior design projects, including working through our auto bottom erector and design concepts for a more friendly adjustable hopper.

We have also collaborated on their engineering ambassador program, which hires rising sophomores to work with grade school students to encourage them to explore STEM fields through hands-on learning activities.