Rugged, Flexible Horizontal Case Packing for a Wide Range of Applications

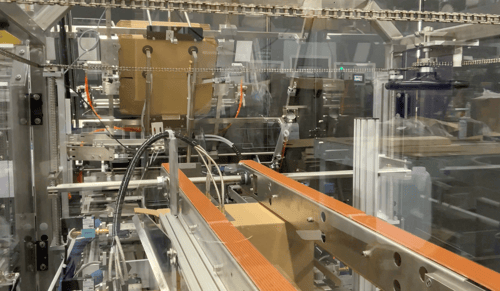

The Econocorp Econocaser is a compact, economical horizontal end-load case packer engineered to deliver consistent, reliable performance for a variety of secondary packaging applications. Built for flexibility, the Econocaser handles a broad range of corrugated cases, accommodating both RSC (Regular Slotted Case) and HSC (Half Slotted Case) designs with ease.

This versatile case packing system offers hot melt glue sealing or pressure sensitive tape closure, features quick and simple changeovers, and is constructed with a heavy-duty stainless steel sanitary frame—all within a small footprint. With speeds of up to 10 cases per minute, the Econocaser is ideal for industries including frozen foods, snack foods, puzzles, beverages, oils, cereals, cosmetics, and more.

Integrated End-Load Case Packing with Flexible Closure Options

- Case Erecting: Flat cases are automatically picked from the magazine using a vacuum arm and erected into an open position. This ensures proper case formation for a wide variety of case styles, including RSC and die-cut formats.

- Case Loading: Products are either hand-loaded at the loading station or automatically loaded using optional loading devices, depending on the production requirements and desired automation level.

- Case Sealing: Once loaded, the open case is indexed forward where it is sealed using either hot melt glue or pressure-sensitive tape. The closure method can be configured based on material type, customer preference, or product protection needs.

- Case Discharge: The sealed, finished case is then automatically discharged at an ergonomic working height, ready for downstream palletizing, shrink wrapping, or direct shipment.

Built for Sanitary, Rugged, and Space-Efficient Performance

The Econocaser is built with a heavy-duty welded stainless-steel frame to meet sanitation standards and deliver the rugged durability needed for continuous case packing operations. Its strong construction ensures reliable, long-term performance across a wide range of production environments.

For facilities requiring elevated hygiene standards, a washdown option is available to support frequent cleaning and help meet food, beverage, and pharmaceutical industry regulations.

Despite its heavy-duty build, the Econocaser maintains a compact footprint and is caster-mounted for easy relocation, integration, and reconfiguration in space-constrained production lines. Its design makes it simple to reposition the machine as facility needs evolve without major disruption.

With simple mechanical adjustments and fast size changeover features, operators can quickly switch between different case sizes and packaging formats, helping reduce downtime, maintain high throughput, and keep production running efficiently.

Econocaser Specifications

| Specifications | Details |

|---|---|

| Speed | Up to 10 cases per minute |

| Materials Supported | Corrugated and Folding Board |

| Case Styles | RSC and HSC Designs |

| Closure Methods | Hot Melt Glue or Pressure Sensitive Tape Closure |

| Size Range | Min: 8" x 6" x 4" Max: 24" x 16" x 18" |

| Power Requirements | 220V, 50/60 Hz, Single Phase |

| Air Requirement | 80 PSI (5.5 bar) |

| Shipping Weight | Less than 1,900 lbs (860 kg) |

| Footprint | 165” L x 120.4” W x 84.2” H |

Econocaser Features & Benefits

Integrated Form, Load, and Seal Operation

Flexible Case Handling

Quick and Simple Changeovers