Efficient, Flexible Semi-Automatic Carton Sealing

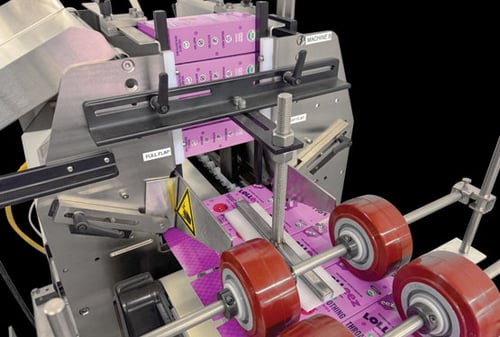

Part of the EconoCore line, the Econocorp Twinseal is an economical, semi-automatic carton sealer designed to glue and seal two outer flaps of a corrugate or paperboard carton simultaneously. With a compact footprint, a flexible infeed option, and quick-change over adjustability, the Twinseal is perfect for businesses looking to scale their packaging output with minimal floor space and investment.

Whether you’re sealing cartons in cannabis, food, industrial, or craft beverage markets, the Twinseal delivers dependable performance with simplicity and speed.

Get Your Flexible, Semi-Automatic Carton Sealing Solution Fast

The Econocorp Rapid Delivery Program addresses the growing demand for more nimble deployment of high-value cartoning and end-of-line packaging equipment in today's fast-paced manufacturing environment.

Customers can now receive fully configured Twinseal machines within 2-4 weeks, provided their requirements fall within standard machine size ranges and configurations.

The program features streamlined specifications with pre-approved carton structures, including full flap seal end designs for Twinseal units.

Compact Footprint, Space-Saving Design with Fast, Flexible Changeovers

Designed for entry-level automation and low-to-moderate production lines, the Econocorp Twinseal delivers dependable performance with speeds of up to 30 cartons per minute. It’s an ideal solution for small-to-medium operations looking to increase packaging efficiency, reduce manual labor, and streamline sealing processes without investing in large, complex systems.

With its compact footprint, the Twinseal fits easily into tight or space-constrained environments, making it perfect for facilities with limited floor space or those looking to add automation without reconfiguring their current layout. It’s also designed for seamless integration into current production lines, helping minimize set up time and avoid disruptions to ongoing production.

Versatile Carton Sealer for Manual or Conveyor Infeed

The Twinseal offers flexible infeed configurations, choose between manual hand load or an optional choke-fed belt conveyor to best fit your operation. The system accepts loaded cartons with closed inner flaps and handles the gluing and compression of outer flaps automatically.

Twinseal Specifications

| Specifications | Details |

|---|---|

| Speed | Up to 30 CPM |

| Carton Size Range | Min: 1" x 1" x 3" – Max: 12" x 4" x 12" |

| Carton Materials | Paperboard, Corrugate |

| Closure Method | ECONOSEAL Hot Melt Glue System–Dual flap seal |

| Infeed Options | Manual load or Choke-fed belt |

| Voltage & Power | 220V, 50/60 Hz, Single Phase, 1400W Glue Pot |

| Air Requirements | 80 PSI, 9 SCFM (255 L/min) |

| Weight | Under 300 lbs (136 kg) |

| Footprint | 50”W x 31”H |