Flexible End Load Cartoning in a Compact, Scalable System

The Econocorp E-System 2000 is a flexible, intermittent motion horizontal cartoner designed for companies ready to move from manual packing to efficient, semi or fully automated cartoning solutions. Ideal for small to mid-size operations seeking to improve throughput within a compact footprint.

Engineered to erect and seal end load cartons with minimal operator effort, the E-System 2000 provides a straightforward path from manual packaging to automation. As part of Econocorp’s trusted Econocore line, the E-System 2000 supports both manual and automatic loading, offers glue closure, and handles paperboard or corrugated materials, making it highly adaptable to a wide range of packaging applications.

With user-friendly operation, durable construction, and a low total cost of ownership, the E-System 2000 is a smart choice for companies looking to improve packaging efficiency, streamline production and maximize floor space.

Get Compact End Load Cartoning Fast With Our New Rapid Delivery Program

The Econocorp Rapid Delivery Program addresses the growing demand for more nimble deployment of high-value cartoning and end-of-line packaging equipment in today's fast-paced manufacturing environment.

Customers can now receive fully configured E-2000 end load cartoning machines within 4-8 weeks, provided their requirements fall within standard machine size ranges and configurations.

The program features streamlined specifications with pre-approved carton structures including full flap or economy flap options for E-2000 machines.

Compact End Load Cartoning for Growing Operations

The E-System 2000 isn’t just compact—it’s built for performance and flexibility, making it ideal for growing operations with evolving production demands. Starting as a manual load cartoner, it can be easily upgraded with a belt conveyor or bucket conveyor for more automated loading, helping reduce labor and increase efficiency.

Its intermittent motion operation makes it ideal for applications up to 25 cartons per minute—perfect for companies introducing cartoning automation or managing multiple product SKUs. The system’s compatibility with both paperboard and corrugated materials allows it to handle a wide range of packaging applications without the need for multiple machines.

Built with flexibility in mind, the E-System 2000 can be configured for right-hand or left-hand loading and straight back discharge, allowing seamless integration into existing lines or space-constrained production environments.

Reliable Performance with Simple Operation

The E-System 2000 delivers reliable, high-performance cartoning solutions in a compact footprint. Its space-efficient design makes it ideal for facilities with limited room, while still providing the power and functionality needed to support consistent, efficient cartoning operations.

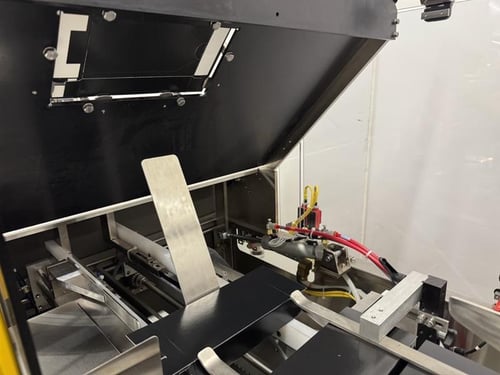

The cartoning process begins with a vacuum arm that pulls each carton from the magazine and erects and places the carton at the dedicated load station. Products are then loaded – either manually or via an optional automatic infeed. Once the product is in place and the closure cycle is activated, the system applies a hot melt glue seal. The complete, loaded, and sealed carton is automatically discharged from the machine at a convenient working height.

This simple, efficient workflow enhances productivity and ensures consistent, high-quality packaging – while keeping operations running smoothly with minimal downtime.

Simple, Serviceable, and Built to Last

At Econocorp, we understand that maximizing output is essential for every operation. That’s why the E-System 2000 is designed with rugged components, minimal moving parts, and a straightforward mechanical design, making it easy to operate, maintain, and service with minimal downtime or disruption.

Featuring PLC-based controls, intuitive functionality, and quick changeover capabilities, the E-System 2000 allows operators to switch between product sizes and packaging formats quickly and efficiently—without the need for extensive training or technical expertise. This level of flexibility is essential for companies managing multiple SKUs, short product runs, or seasonal production shifts.

And when support is needed, you can count on our responsive, US-based service team for expert guidance, spare parts, or technical assistance—keeping your packaging line running at peak performance.

Scalable Automation with Flexible Infeed Options

The E-System 2000 is designed to grow with your operation—offering flexible infeed configurations that support both manual and automated product loading. While it comes standard with a manual hand-load station, the system can be upgraded to meet increasing production demands with additional automation options.

For streamlined handling of uniform products, the belt conveyor infeed offers a simple and effective method of transferring product into the carton. For more complex packaging applications, the bucket conveyor system provides accurate, indexed delivery that improves consistency and reduces operator workload.

These infeed options are ideal for businesses scaling up from manual processes or seeking to reduce labor costs while improving throughput and loading precision. Whether you're running short product batches or managing a multi-SKU line, the E-System 2000 provides the flexibility and upgrade path to meet your needs, making it a long-term, adaptable solution for growing packaging operations.

E-System 2000 Specifications

| Specifications | Details |

|---|---|

| Speed | Up to 25 cartons per minute |

| Carton Sizes | Min: 1” x ¾” x 4” Max: 12” x 4” x 12” (Custom sizes available) |

| Materials | Paperboard & Corrugated |

| Closure Types | Hot Melt Glue |

| Infeed Options | Manual, Belt Conveyor, Bucket Conveyor |

| Power | 220V, 50/60 Hz, Single Phase |

| Air Requirement | 80 PSI, ~15.8 SCFM |

| Machine Footprint | Under 10 ft long (when manual load) x 4 ft wide |

| Shipping Weight | < 1300 lbs (590 kg) |

| Controls | PLC Controlled; Dual Button Start, Safety Light Curtain |

E-System 2000 Features & Options

Optional automatic loading

Efficient closure methods

Customizable layout